The transformation of industrial big data, empowering the manufacturing industry is a "addition, subtraction, multiplication and division" problem

How should we understand industrial big data, how can industrial big data empower intelligent manufacturing, and how to move towards the future industrial Internet based on intelligent manufacturing?

The path for industry to transform and upgrade

The National Engineering Laboratory of Big Data System Software summarizes the path of industrial transformation and upgrading into the four quadrants of "addition, subtraction, multiplication and division".

The so-called addition and subtraction are intelligent manufacturing. Intelligent manufacturing pays more attention to the internal affairs of the enterprise. In a narrow sense, intelligent manufacturing focuses on manufacturing, that is, the production process. In a broad sense, intelligent manufacturing includes the entire life cycle of an enterprise, from R&D and design to manufacturing to operation and maintenance services.

Intelligent manufacturing is nothing more than adding something to or subtracting something from the existing process. It can basically be summarized in eight words: quality improvement, efficiency increase, cost reduction, and risk control. Today, what smart manufacturing does is addition and subtraction.

But adding and subtracting is not enough in this era. For example, if a private equity institution invests in a company, if the company makes a little addition every year, investors may not be satisfied, but hope that the company will achieve exponential growth.

How to achieve? The Industrial Internet may be the way to realize multiplication and division. Multiplication is the platform effect. For example, Taobao, which accommodates countless stores to make money by opening stores on its platform, is a case in point. But in the industrial field, is it possible to build an industrial Internet platform?

Take the clothing industry as an example. The traditional first-generation clothing companies have their own designs, factories, and stores, that is, a complete industrial chain. The second generation of apparel companies abandon the factory and choose full OEM production, and switch to marketing, with stores as their assets. In the Internet age, clothing companies have neither factories nor stores, and the cost is almost zero. All stores rely on Taobao and are only responsible for rapid design and control of the supply chain. Although the final "total plate" is not necessarily as large as traditional enterprises, But the profit margin is high. Therefore, division is to focus on the company's core competitiveness.

Asset-light and high-profit operation is the way for Chinese SMEs to innovate and start businesses in the future. Building the platform ecology of the industrial Internet does not mean that only this platform can make money, but that everyone on the platform can make money.

Three levels: classification of industrial big data industry

The National Engineering Laboratory of Big Data System Software has contacted and has done a lot of industrial big data applications, and divided them into three levels.

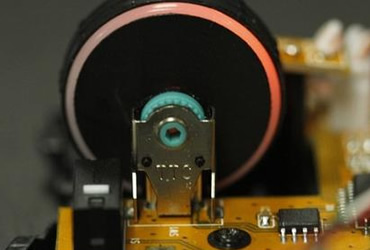

The first level is the unit level, that is, for industrial equipment, it is not limited to remote operation and maintenance of equipment, but also includes early warning of equipment failure, failure analysis, and optimized operation of equipment, asset management, and so on.

First of all, we need to perform accurate digital measurement of the operating state of the equipment. This measurement method is actually to discretize the continuous space of industrial big data. This continuous space is very complicated, and the physical quantities that can be measured, accuracy, and the number of sensors are limited, so full-space sampling cannot be achieved. However, as the level of digitization increases, the progress of informationization, and the iteration of intelligent applications, the measurement process in the future will also be upgraded.

The second level is the factory level. This level does not focus on individual equipment, but on the operating efficiency, product quality and safety, and environmental issues of the entire factory. Industry stresses factors including people, materials, processes, equipment, and the environment, which can act synergistically in complex dynamic systems.

Assuming that the whole of China is regarded as a big factory, how can we improve our efficiency in the industrial chain? Today we are doing industrial big data and doing "smart +", which is the purpose.

First of all, we must answer where the data is. In fact, the data is in any place. In the past, industrial data management was relatively rough, and the traditional informatization field was relatively better than management informatization. Now, many industrial data are only used for monitoring and data playback when failures occur. How to use these data to do the integration of the two (informatization and automated data integration) remains to be verified.

How does the third level get other relevant data? For example, to automate the construction of excavators, you need to understand GIS data and environmental data, but these are not data owned by traditional manufacturing companies. This shows that the connotation of today's industrial big data is much greater than the connotation of traditional data. Automation and cross-border overall data constitute a system of industrial big data.

Classification and challenges of industrial big data

In fact, industrial data has three characteristics:

The first feature is multi-modality. In the past, data was simply and roughly divided into structured data, semi-structured data, and unstructured data, but this is not the case for industrial enterprises. A lot of unstructured engineering data that seems to be in a different format today is different when it is actually opened. The use efficiency of unstructured data depends on the degree of structure, and only structured data can be used efficiently;

The second feature is high throughput. Many devices are non-stop, all data is continuously generated 7*24 hours, and the amount is very large;

The third characteristic is strong association. In different industries in the industry, data association follows different rules rather than simple aggregation.

Therefore, the characteristics of industrial big data itself have brought many challenges. In addition to the challenges of data acquisition, there are also challenges of data analysis and application.

The biggest limitation here is causality, that is, data-driven methods can only tell us relevance, but cannot tell us causality. For example, Taobao recommends products, only knows to recommend related products, but does not care about the cause and effect of this matter-why the user is such a person. But this is not feasible in industry, especially in control, so the model needs a long time to analyze and verify.

There are white-box models and gray-box models in the industrial field. The white-box model is the industrial mechanism. Enterprises will design procedures, product structures and processes based on the industrial mechanism. This is the first step. After they are designed, there will be a lot of uncertainties in operation. The elimination of these uncertainties depends on the experience of experts and craftsmen to make the whole process production more stable and efficient. This is a gray box state. The data model that no longer analyzes and understands the mechanism and knowledge itself is a black box model.

The essence of industrial big data and industrial intelligence is to quantify these experiences and knowledge, dig out the tacit knowledge that is not in the mind, or try to find the statistical relationship through the data method, and then return it to the craftsman for analysis.

Industry is industry. It has existed for longer than informatization, and has more accumulation than informatization. Big data and artificial intelligence technology only bring small changes to industry and try to help it eliminate uncertainty.

Application of big data and artificial intelligence in industry

The first is smart manufacturing. For example, if the yield rate of a machine tool drops, the machine tool can guess that the tool may be worn out, and actively propose to change the tool, or if the furnace temperature is overheated, it will automatically lower the temperature by two degrees. If the device can inform and change autonomously, instead of operating according to the pre-set logic, this is intelligent.

What should a real digital workshop look like? There are three levels:

The first layer is big data integration. Big data can establish a data integration system, allowing decision makers to see what is happening in each production workshop, what are the control parameters, and what are the detection parameters. Such a data integration system with materials as the center and process flow as the axis can provide more and better decision-making information for adjustment workers;

The second layer is big data statistical analysis. Can the data of good batches and the data of bad batches be superimposed and compared to see the difference in control parameters? Big data can guess the cause of the problem, at least it can be sorted, so that the adjustment workers can check and adjust according to the sort;

The third layer is the mechanism model. Through a large amount of data and feedback, industrial enterprises can build a relatively accurate and positive simulation model, debug it in the digital twin, digital space, and finally test it in the factory. This is the intelligent system brought by the digital twin.

So what has the logic of the Industrial Internet changed for smart manufacturing? From a business perspective, the Industrial Internet pays more attention to the boundaries of the Industrial Internet rather than the production links within the enterprise. It can be summarized into three integrated cross-borders:

The first is business integration and cross-industry. Through the expansion of the upstream and downstream business boundaries of the industrial chain, companies can try to integrate the upstream and downstream, and we can also serve the downstream and downstream. We are a large factory from the perspective of industrial chain synergy;

The second is the integration of data chains and cross-industry. The expansion of business has brought about the expansion of data boundaries. Today's data is not limited to the original data of the enterprise. For example, to serve builders, environmental data, operational data, and weather data are needed;

The three most fundamental is technological change. Compared with the development of IT technology, industrial software and IT industry are not in the same development curve, but now through cloud computing technology, users can do such development in a light weight, which can be produced in many fields. Technology spillover opportunities. The emergence of the industrial Internet platform allows industrial companies to deposit simulation models that have spent a lot of time on research and development into small and sophisticated new forms of industrial software.

沪公网安备 31011402006992号

沪公网安备 31011402006992号